Meusburger Georg GmbH & Co KG is an Austrian manufacturer of standard elements for tool and mold making with more than 24,000 customers worldwide. By replatforming its system landscape into a "seamless customer experience" - i.e. linking customer account, web shop, website and configurators in a single frontend - Meusburger is once again setting the standard in B2B commerce.

Meusburger was founded in 1964 as a one-man business in Dornbirn and is still family-owned today. Its products serve as the basis for production processes in tool and mold making. This makes Meusburger a prime example of a hidden champion with global market leadership. In addition to optimizing its product portfolio, the supplier of standard components is also constantly developing its digital capabilities - from its own software products to an e-commerce landscape and product configurators.

327

Mio

revenue in 2023

56

%

digital Revenue

24

customers

🏆Multiple awards

We are proud to have received the “Best of Consulting Award 2025” from WirtschaftsWoche and the “Mid-Market Manufacturer of the Year” award from the B2B E-Commerce Association. These awards are not only the result of individual projects, but also proof of the effectiveness of our own transformation.

In 2023, we began to systematically integrate the consulting business into TOWA. This marked our transition from a traditional digital agency to a transformation partner for upper mid-sized companies. In 2024, we took a conscious step away from pure marketing toward commercial excellence and business transformation, with the goal of providing B2B companies with comprehensive support in their go-to-market transformation. The Meusburger portal also shows how technology, data, and strategy interlock to enable the holistic digital transformation of hidden champions.

Seamless Customer Experience

After developing the product vision and replatforming roadmap, we first introduced the customer account (KIS), followed by the shop and website. The website includes numerous digital services, such as complaint management, parts lists, CAD integration, order management, document management, and CPQ for up-to-date price calculation.

In 2024, the first configurators were launched, enabling full parallel operation. With this foundation in place, various user groups were introduced to the new design and functions gradually. This enabled deactivation of the old configurators in 2025, leaving only the new platform available to customers.

Digital Services

Meusburger offers its digital services to various user groups, including in particular

purchasers

Design engineers

Toolmakers

Depending on the customer group, intelligent services have been developed over the past decades that could be used as applications in different places.

One of the goals of the replatforming was to bring these services together in a single experience and provide them with a modern user experience.

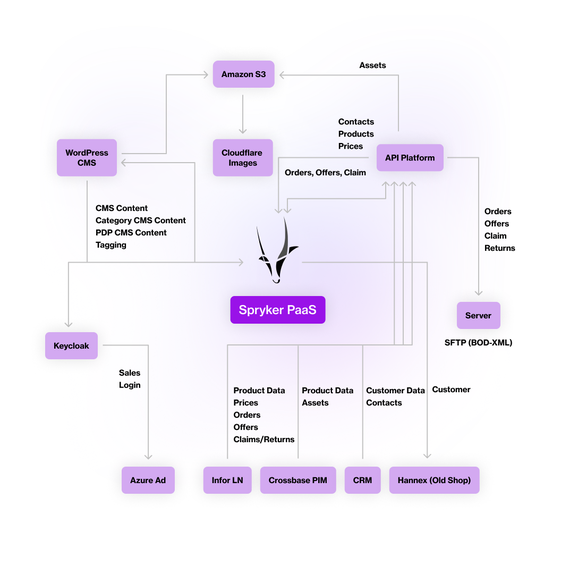

The IT Architecture

The WordPress CMS manages all content data, including categories and product details. This data is transferred to Amazon S3 and Cloudflare Images, where it is optimized.

Keycloak and Azure Active Directory provide secure authentication and a dedicated agent login. The API platform enables data mapping and exchange between Spryker PaaS, Infor LN, Microsoft Dynamics CRM, CPQ, and Crossbase PIM.

This architecture offers scalability, security, and efficiency through seamless backend integration, consistent data management, and up-to-date pricing for all products.

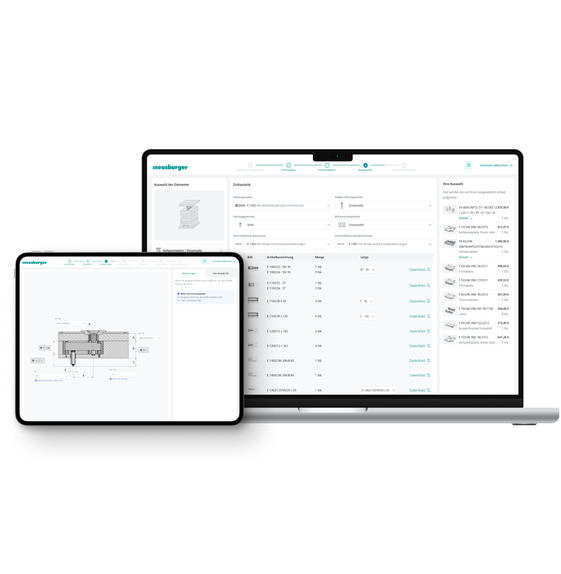

Customized Product Configurators: Precision Meets Digital Excellence

As part of the project, we collaborated to develop highly complex product configurators that integrate seamlessly into the new B2B commerce architecture. These configurators include mold assemblies, punching frames, punching and bending frames, built-in parts, and hot runner systems. Specific configurators were developed for each product category to guide customers through the selection process.

Highlights

Interdisciplinary collaboration: Meetings and workshops were held with all relevant departments to precisely identify and prioritize requirements.

Well-thought-out concept and design: Each selection is designed and structured in a technical, logical, and visual manner.

Interactive step engine: Users can go through their configuration step by step, with each step taking into account previous selection decisions.

Automatic calculations: After each selection, prices, technical data, and availability are updated and displayed.

CAD integration: Each configuration automatically generates precise CAD data that can be used directly for production.

Dependency management: Complex product dependencies from various systems such as PIM and ERP have been taken into account to ensure error-free ordering and production.

This tailor-made solution enables Meusburger to offer its customers an unparalleled digital experience while efficiently optimizing internal processes.

Agile software development

The project's high complexity made agile work essential. Although the vision and approach were clear, numerous questions arose along the way that could only be answered through iterative and collaborative efforts. As part of this collaboration, we chose to use Scrum for agile development. Two agile teams and one UX team were embedded in a PMO structure. This enabled us to meet governance requirements and stakeholders' needs.

Integration into the review process enabled the project team to track development progress. Joint retrospectives enabled continuous improvement of collaboration.

Furthermore, joint control was implemented at the level of epics and user stories. This ensured budget stability for the stakeholders and was available on a daily basis.

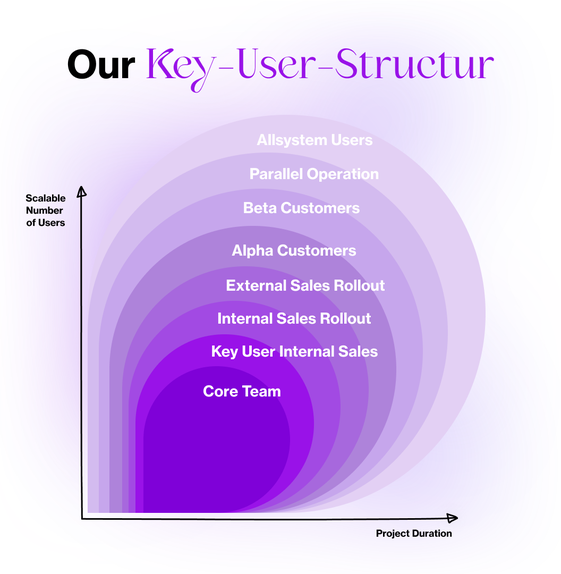

Change Management & Transformation

Our project at Meusburger shows how effective change management, digital transformation and roll-out management can lead to success.

The targeted development of a key user structure created clear responsibilities and optimized communication channels. Key users supported the project team in testing, training and portal optimization. The phased roll-out started with a small core team and was gradually extended to all user groups.

This approach promoted acceptance of the new solution, enabled smooth onboarding and reduced pressure on the entire organization by working in parallel. This ensured a successful implementation and sustainable results.

DevOps & Quality Assurance

For Meusburger we use the powerful Spryker platform on AWS. Spryker offers comprehensive DevOps support and a self-service platform, complemented by our cloud-based tools. This combination ensures high quality standards in the long run.

Our deployment processes are automated. We use Spryker's architectural patterns and QA tools, as well as PHPStan to monitor code quality. Our team follows a classic testing pyramid.

To improve our development processes, we analyze data from the ticket system and Git in a dashboard and monitor DORA metrics. These help us to evaluate and optimize the effectiveness of our actions.

In this way, we ensure the quality of our project and create a solid foundation for Meusburger for years to come.

Handover & Enablement

The goal is to empower the organization through pair programming, pull requests, knowledge sessions, Figma training, and CMS workshops in the specialist departments.

After the second project phase was successfully completed, systems such as JIRA were transferred to Meusburger.

This created a sustainable setup that enables more collaborative and intensive work.

Let´s talk about B2B Commerce Replatforming